Base oil is a fundamental component in the formulation of lubricants, including motor oils, greases, and metalworking fluids. Extracted through the refining of crude oil, base oils are tailored for specific performance characteristics, with viscosity across varying temperatures being a key factor.

Production Process

Base oils are produced by heating crude oil in a distillation tower to separate light and heavy hydrocarbons. Light fractions are converted into fuels like gasoline and diesel, while heavier fractions are used to produce bitumen and base oils.

The most commonly used crude for base oil production is paraffinic, though naphthenic crude is also used for applications requiring improved solubility and low-temperature properties.

Advanced refining techniques such as hydrogenation are employed to remove impurities like sulfur and aromatics, yielding highly pure base oils suitable for demanding applications.

Applications

• Motor oils

• Lubricating greases

• Metalworking fluids

• Hydraulic oils

• Industrial lubricants

Types of Base Oil

1. Mineral Base Oil

Derived directly from refined crude oil. Only 1–2% of a crude barrel becomes base oil; the rest is refined into fuels and other products.

2. Synthetic Base Oil

Produced via chemical synthesis, synthetic base oils offer excellent thermal stability and uniform molecular structures. Common types include:

• Paraffinic synthetic oils

• Naphthenic synthetic oils

• Polyalphaolefins (PAOs) — used in Group IV base oils

• Esters, PAGs, and biolubes — categorized under Group V

API Base Oil Groups

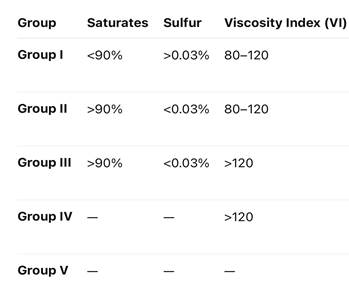

Base oils are categorized into five groups by the American Petroleum Institute (API):

Grades of Base Oil

Base oils are also identified by Solvent Neutral (SN) grades, based on viscosity at 40°C:

• SN 150

• SN 300

• SN 500

• SN 650

Lower SN grades are lighter in color and viscosity; higher grades tend to be darker and more viscous.

Desirable Characteristics

• Excellent thermal and oxidative stability

• Stable viscosity across temperature ranges

• Low volatility

• High flash point

• Light color and low sulfur content

• Low Total Acid Number (TAN)

• Strong operational consistency

Packaging Options

• Steel drum

• Flexitank

• IBC (Intermediate Bulk Container) tanks

Storage Guidelines

• Ideal storage: Indoors, at consistent temperatures (~25°C)

• Outdoor storage: Must be covered and shielded from sunlight, rain, and snow

• Container compatibility: Safe in mild steel tanks

Safety, Health & Environmental Notes

• Stable under standard conditions

• Non-corrosive and minimally irritating

• Avoid prolonged or repeated contact with used oil

• Handle with care and follow local environmental guidelines